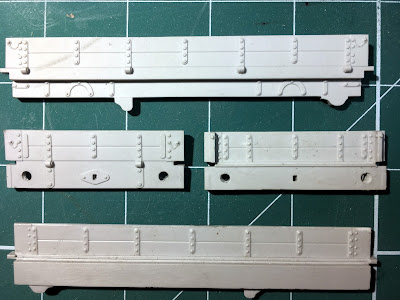

After building a couple of ballast wagons the hard way, as I described in previous posts, I decided to investigate a quicker way to build a wagon as I needed a few more to make my ballast train more credible. So, in collaboration with a mate who specialises in model aircraft kit accessories, I produced these interlocking resin sides and ends. The floor, "w" irons, wheels, buffers, couplings, axle boxes, springs and brake gear are not supplied but are all readily available from the trade.

The castings are available for purchase at £20 per set + post/packing at cost £1.50 (UK).

Contact Pete on...

armstrongps1@gmx.com

07342 637 813

Features.

There is an inner step between the side planks and the solebar which it is intended that the wagon floor sits on. If this is made from sheet metal then the "w" irons can be soldered beneath which makes for a robust construction. The metal floor can be faced with Slaters' 7mm Plastikard planking to make a convincing wagon bed for an empty wagon.

The sides and ends are scale 3" thick and interlock to facilitate construction.

The draw plate has a square hole to take a CPL wagon hook (my preference) , or you can scrape the draw plate off and replace it with a different plate and hook.

There are downward projections mounted on the solebar to which the brake lever and brake handle are fixed, they are designed for Drummond's patent each-side brake gear. It's quite a simple matter to make the parts needed from 0.45mm brass or nickle silver strip using Peter Tatlow's drawing in "HR Carriages and Wagons" as a guide.

The fastening that holds the drop sides and ends in place, along with its chain are part of the casting, which saves a lot of time and fiddling.

No comments:

Post a Comment