|

| HR Loch class tender original length though without rear toolbox. |

The main structural components of the tender are from the Lochgorm kit though the tank corners and curved coping are sections cut from brass tube as I could not bend the material of the kit, the coping was too intransigent and the corners kinked when I tried to bend them due to the oversize holes for the corner handrails. The steps still need improvement to remove the etched outlines above the horizontal part of the step.

|

| HR123 in 1923. Courtesy of the Highland Railway Society. |

A rear view of Loch an Dorb at Blair Athol in 1923 in the HR collection at Am Baile shows her running with an original tender with a rear toolbox. However the above picture, which I believe was taken in either 1923 or shortly after, shows her in HR livery with what I interpret as an original length tender though with the rear toolbox removed. A shorter one can be seen mounted behind the driver. The tender has at this time not yet been lengthened to the full length of the footplate. This is the style of tender that I've modelled (above).

|

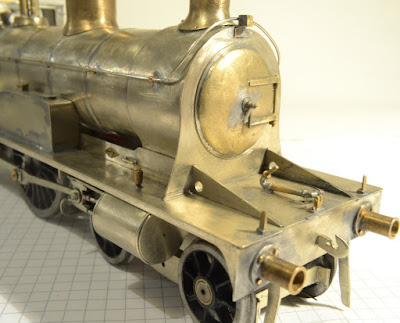

| Smokebox and footplate detail |

The inspection covers above the slide bars were represented on the footplate by an unsightly etched outline. I cut along the etched lines to create a rectangular hole in the footplate and made an infill to represent the covers which just need some tiny hinges to complete the effect. There may be something available in Archer Surface Detail transfers that will fit the bill.

|

| Cab roof constructed from nickel sheet silver with brass extruded cross ribs. |

The roof is made from sheet nickel silver though the front curve is a section of brass tube, transverse ribs are extruded brass section. The tablet catcher on the cab side is an LGM casting to which I've added a handle that protrudes into the cab.

|

| Detail of cab and backhead with roof removed. |

There are three sources of information for the backhead detail; a drawing by Peter Tatlow; a GA of the 1917 engines and of course the backhead of the preserved Jones Big Goods in the Transport Museum in Glasgow. Though I've mainly based the details on Tatlow the other sources have helped too. Castings are mainly LGM, some of which are a little oversize, they have been reduced to the right scale with an unavoidable though slight loss of detail.

The oversize inside splashers contribute to limit the space available for a crew, which in the case of a 4-4-0 with so visible a cab interior, I consider mandatory.

The fall plate is attached to the engine and because of the protruding side wings and stanchions on the tender footplate I've had to make the fall plate cut-outs oversize to accommodate these as there is a good deal of movement between tender and engine on corners. Fall plates and tight corners are not compatible and neither I suspect are cab doors, particularly the bi-fold variety that the Lochs carried, though this is a problem I've not yet examined closely.

I don't think the engine will ever be happy running in reverse, however as the Highland did not encourage this practise it shouldn't present a problem.