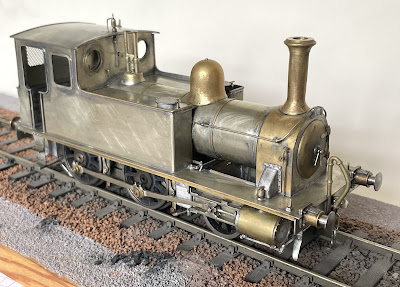

Construction of HR118 is complete, it has taken the best part of six months to get to this stage. I'm working on a suitably posed crew now before painting the engine. The white metal castings I made from my own masters are in evidence on the pictures on this post. Particularly in view above are the sandboxes front and rear. Below you can see the water filler castings on the tank tops and the curved covers that sit on the footplate either side of the smokebox.

|

| The cast white metal cover beside the smokebox is well seen in this view as are the buffers which have tread-plates added. A rod passes in front of the engine below the buffer beam which operates the cylinder drain cocks. |

|

| The front sand box snuggles behind the motion plate, above it on the footplate sits the sand box mechanism with an operating lever disappearing behind the side tank. |

|

The position of the brake stanchion is established from photographic evidence though much else of the cab interior detail is an imaginative reconstruction. I've included as much detail as possible to bring the cab interior to life although most of this will be masked from the outside when the crew is in position. The coal on the floor is small coal as the bunker opening on the outside is only about 3" wide.

|

|

| The back-head was built by myself though the castings seen here are commercial ones modified to fit the situation. I'm sure there was much more to it than this, but I have no information to work with. |

The engine has been weighted with lead strip added below the cab and in the side tanks and will haul 10 wagons and a brake van with ease. I imagine the real engine might manage about the same; it was not a powerful engine, its tractive effort being less than half that of a Yankee Tank.

|

| The restricted bunker opening is in evidence here. The rear sand box can be seen behind the cab step, though how it was filled is obscure, neither is the sand box mechanism in evidence. |

No comments:

Post a Comment