|

| An incomplete Merrie Carlisle had a test run on the club layout in Carlisle recently, she went well and was well received by the members. |

The smokebox has yet to be soldered into place and at this stage the wrapper has no rivet detail, nor do the cab side sheets. I plan to add the rivets later when construction is complete and I've done some research into the possibilities, of which there are four...

1. Brass rivets soldered or glued into appropriate holes. The rivets heads on the real engine are 3/4" d. which in 1:43 scale is 0.435mm. I think 0.5 would be near enough, though I'm sure drilling 250 rivet holes would be a task expensive in small drills.

2. HGW cast resin transfer rivets seemed a good idea and indeed they are very effective, easy to work with and leave no backing on the model as this is peeled away after the transfer sets. Unfortunately they're too small for gauge O locomotives as they're designed for model aircraft, 0.25 is the largest diameter of rivet they make and though they're fine for aircraft, to us they're mere pimples.

3. Archer Surface Detail transfer rivets are the favourite at the moment, they make O gauge rivets about the right size which adhere well to the primer coat. I've experimented and rubbed them with my finger and they stay put. They stand proud of the surface of the model by 0.12mm which is nearly 1/4" and a little on the low side compared to a brass rivet. I'll have to try them and see how convincing they are, this is after all an experiment. Another reservation I have is that the resin rivets are carried on a carrier film though this is very thin and I think will disappear under the paint.

4. Small Shop produce a "Nutter" tool which makes rivet and nuts and bolt heads that are glued in place with varnish. I've only seen a video of this in action but on the face of it the tool looks like a viable though rather expensive proposition.

|

| The wheels are insulated at the rim and and are cast and turned to size by JPL Models. |

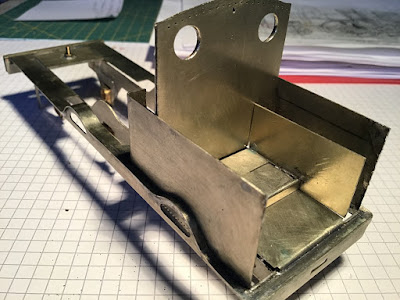

The motor is restrained by a vertical member which engages in a hole in the top of the motor.

I may replace the M1824 with a more powerful M1833 if the locomotive proves underpowered, I think there's probably room for one.

The front wheels are sprung individually, following Geoff Holt's example, this arrangement is just visible bottom right.

|

| There is a very visible void beneath the boiler so inside motion will have to be fitted, though I don't know whether I can make it work. |

The upper part of the motion plate is in place between the upper part of the frames, which are attached to the footplate. The lower part of the motion plate will be attached to the working frames below and will carry the slide bars and provide support for the valve rods. The LNWR Precedents were fitted with Alexander Allan's straight link valve gear, mine will be fitted with the nearest to that ideal that I can manage.

Electrical pick-up is by the so called American system, the current is led from the tender to the motor through the drawbar, which is insulated from the engine, using a method described by Nick Baines. I've attached a pick-up wire to the drawbar at the tender end which bears on the bottom of the tender floor above to ensure a good contact. Without this addition contact with the tender was uncertain and resulted in uneven running.

|

| There's only a 9" gap between buffer beam and smokebox front so it's a tight fit for the cylinder lubricators which were modified for this situation from LGM castings. |