|

| Renewed Precedent Class, Merrie Carlisle, LMS 5050 in 7mm scale |

The engine is built in nickle-silver, without the aid of a kit, though the tender is a Gladiator Models product, to which I made a few improvements. It is intended to finish the model in early LMS red, Merrie Carlisle being one of only four of this class to be turned out in full red passenger livery. When the engine first appeared in its new livery it carried number 5050 on a smokebox plate and retained its original socket lamp-irons. The Bill Finch Portfolio of Locomotive Details, published by the LNWR Society was an invaluable help in building the model. The only kit I know of for a Precedent is a Mercian Models product, which may no longer be in production.

|

| Precedent chassis and mechanism revealed |

Power is provided by an M1824 motor and ABC gearbox, mounted on the front driver and fitted with an MSC flywheel. I could have fitted a more powerful M1833, though there would not have been room for a flywheel. I prefer the smaller motor/flywheel set-up, which greatly enhances the engine's running qualities. Pick-ups are phosphor-bronze wire wipers on the left-hand wheels; the right-hand wheels are shorted by hidden wires. The front carrying wheels are from Slater's, who do not produce suitable Precedent driving wheels, those I used were supplied by JPL and may not be available now.

|

| Allan's straight link motion, simplified by the omission of the drop-links, fills the gap under the boiler. The valve rods pass through a gap in the motion plate. The sand boxes, which flank the motion plate, are filled with yellow Milliput. |

|

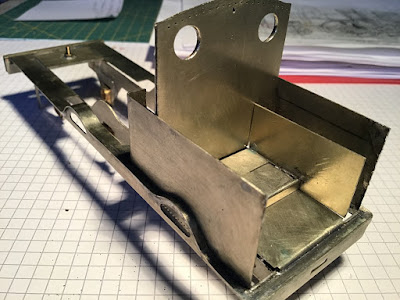

| The inside motion unit removed. |

|

| The tool box castings have been detailed and display how they were fastened to the tender top. |

|

| Under the tender. |

The water pick-up apparatus has not been included under the tender though the double brake pull-rods have been modelled fully. Note the tender buffers, which really work, being sprung behind the buffer beam.

|

| The Crew. |

The loco crew are from my own sculpture and are cast in white metal in my workshop. Both figures are mounted on thin sheet metal bases and secured to the deck with double-sided tape. The fireman stands on the tender fall-plate, his base is made from scrap chequer-plate. The poses of the crew are designed so they relate to both the engine and to each other. They were designed as the model progressed and are an integral part of the model, by no means merely an afterthought.

|

| The brakes are a tight fit. |

|

| A busy cab interior. |

I built the cab interior with the help of castings from Laurie Griffin's range, most of which were modified in some way to suit a Precedent. I used Bill Finch's drawings for reference and don't think I left anything out. The roof, which is attached to the inner skin of the spectacle-plate, can be lifted off, which allows the back-head to be removed too. The spectacle-plate is double-skinned so the window glazing simply slips between the inner and outer skins. The prominent reversing wheel would have been better as a nickle-silver casting to approximate the steel original, but I could only get a brass one, I'm sure it'll look fine with the rim buffed up.

I heard recently that the "Master" himself, James Beeson, painted his reversing wheels red!