|

| Dunrobin frames under construction |

Lochgorm Kits' 7mm kit for Dunrobin, the duke of Sutherland's private engine, was I believe designed originally in 4mm scale by Alastair Wright of 5522 Models and enlarged to 7mm by the late Andy Copp when he took over production of the former's Highland Railway kits in 2011. Alastair began introducing Highland Railway designs to his range in the 1980's; these were hand drawn and, though not designed for 7mm, when enlarged they served well enough though they took their faults with them to the larger scale and magnified a number of these, so some of the etched parts of this kit need to be remade with more accurate replacements.

The chassis (above) is etched in sturdy 0.7 nickel silver and the frames are a respectable 26.4 mm outside diameter so I had to file a bit off the frame bushes to free the wheels. I've introduced a few more cross-members for the cylinder front and rear and for the ash pan. I've ordered an ABC Gears' Pug Special gearbox with a Canon 16 x 20 motor which I think should provide enough power for this little engine. It will sit upright in the firebox and drive the rear fixed driving axle.

|

| Rear bogie complete |

The bogie builds well without much modification and is a solid job. I used Slaters' 1/8" frame bushes for the axles. I plan to mount wiper pick-up wires behind the left hand wheels and short out the wheels on the other side; I'll try silver conducting paint and see if that works.

|

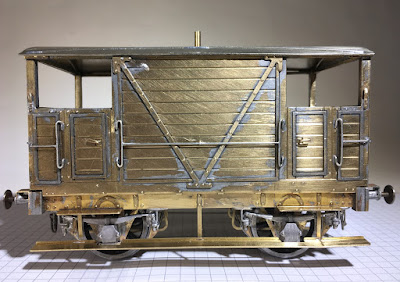

| The superstructure is built on a flat wooden former. |

The boiler in the kit was half-etched to provide boiler bands, which resulted in a flimsy structure, this inadequacy when compounded with a mistake in the diameter of the boiler condemned the offending part to the recycling bin. The front splashers were found to be undersize and new parts were made to replace these too.

I intend to double-skin the cab all round so the acetate glazing will slide between the outer and inner skins; in addition the inner sliding cab windows will be constructed in this manner too. The cab front and rear present no problem though the cab sides will be replaced with more accurate parts to facilitate my ambitious glazing scheme.

Currently the real Dunrobin is undergoing major reconstruction, so there's nothing of her to see at Beamish, her home, though their newsletter is helpful and charts progress. I intend to build a detailed cab interior, though it's going to be some time before I get to this stage, I hope that by then I'll have more information on this aspect of the engine. At the moment some details, particularly of the backhead and controls, are rather hazy.

Photos taken on an Apple I-Phone 11.